Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

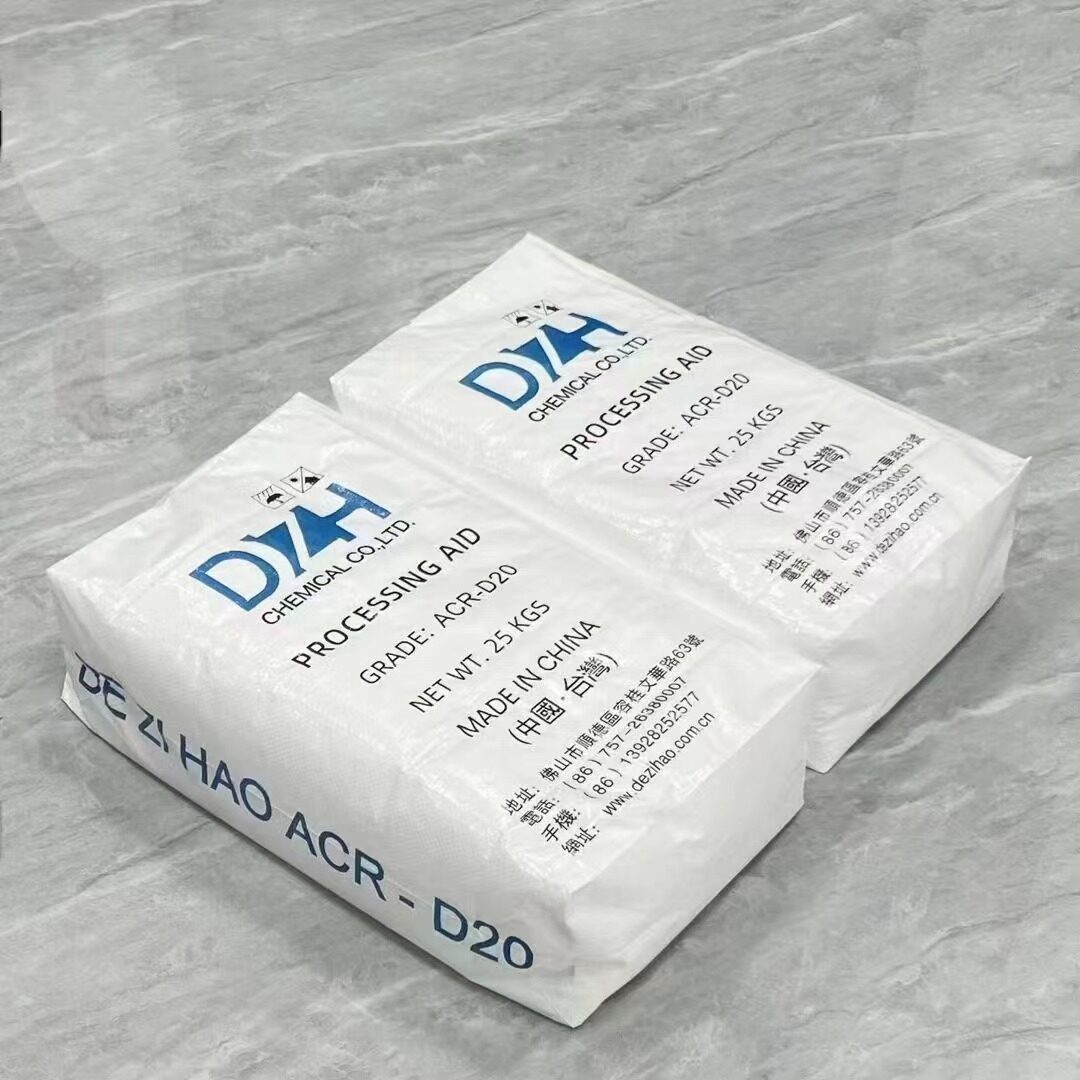

The role of ACR in the PVc processing process

It can significantly shorten the PVC plasticizing time, accelerate melting, improve plasticization uniformity, and effectively control melt rupture. The flowability and elongation of the melt are improved. The surface glossiness of the product is increased, the anti-mold release tension is increased, and the impact strength is improved. ACR is commonly used in low and filled products extrusion, injection molding, and foam products in PVC.

The amount of ACR used is generally 0.5-4PHR. When used in extrusion, the lubrication cost relative to the number of parts increases. At the same time, reducing or not using polar lubricants can cause layer separation in the product.

ACR can also improve rigidity in PVC high-filled products. However, as the amount of calcium powder increases, the brittleness of the surface becomes more apparent after adding ACR.